Read the beginning of the story How to buy Hardwood lumber and Save.

Mill talk made easy (differences between big wood trading home centers and lumber sawmills)

The contrast between the big-box home centers and a sawmill requires explaining. When you go to a big-box store, you'll likely find kiln -dried red oak lumber and poplar planed or surfaced on two sides in 3/4 -thickness(nominally referred to as 1'” thick) in standard widths that include l x2, lx3. lx4, lx6, 1x8, and lx12 . Lengths extend to 12', but you can have boards cut to shorter lengths upon request. All of it is edged to remove wane.

At sawmills, rough stock comes in random lengths and widths and in several nominal thicknesses, such as 4/4 ("four/quarters" or 1~), 5/4

(1';.") , 6/4 (1'/")' 8/4 (2'), and so on. These thicknesses, though, 1 are designated and the board footage calculated before drying and surfacing. You pay retail for the original green thickness, though what you actually get in dry surfaced-two-sides (S2S) hardwood is shown In the chart on the previous post. The point is you can save money by buying full thickness rough·sawn stock and then plane it yourself. For those of you who have a thickness planer and jointer, consider yourselves in the winner's circle. Even if you buy surfaced sawmill boards you save.

Lumber grades a also require getting used to. Typically, big-box stores and wood specialty retailers offer only the top lumber grades of bard wood boards-FAS and F1F (one FAS face). However, depending on your project, you may only need #1 Common wood grade. More good news: You'll find all lumber grades at a sawmill. See "Lumber Grades at Glance" for an understanding of the quality differences found in sawmill wood. Once you know this, you'll know exactly what to ask for.

Grade quality at sawmills runs the gamut from First and Seconds (the best) to #3 Common (the worst) wood grade.

At the sawmill: what you need to succeed.

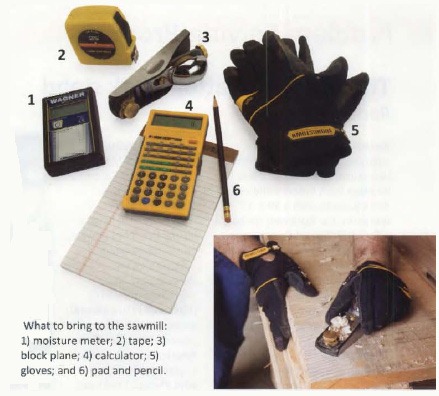

For starters, you'll need a truck or trailer to haul home the wood you buy. Sawmills don't do small-load, local deliveries. Include lots of li ne or cargo straps to secure the load and work gloves to handle rough-sawn stock and avoid splinters. lf the load extends beyond the truck or trailer, tack a red flag to the end, so folks behind you can keep a safe distance.

Next, have in mind exactly what wood you need-the species, thickness, grade, and board feet. (Note that one board foot equals a 1" thick piece of wood that measures 12x12"). lf building a magazine project, bring the cut list and cutting diagram.

How about the wood's lumber condition - are you set up to plane rough sawn stock? Next, decide whether or not you want kiln- or air-dried stock lf you're unsure about the wood's state of seasoning, tote a moisture meter, like Wagner's Digital Moisture Meter to check for dryness.

Ideally, you want hardwood in the 6-8% moisture range for wood furniture. When buying figured wood or quartersawn stock at a sawmill, use a block plane to shave the rough-sawn surface to determine the degree of character underneath as shown above.

Splash on water for an even better view of the grain and color. Lastly, don't forget to check on the seller's preferred payment method before you leave home. Cash may be preferred over a credit card. With that, good luck and happy shopping!

Comments

Post a Comment